Today we’d like to introduce you to William Hadley.

Hi William, we’re thrilled to have a chance to learn your story today. So, before we get into specifics, maybe you can briefly walk us through how you got to where you are today?

Six years ago, my wife handed me a photo of a Christmas ornament and asked, “How do you think this was made?” It looked laser‑cut and engraved to me, and that was the end of the conversation — or so I thought.

Over the next year, she kept asking me what I planned to do when I retired. My answer was always the same: “I’m not sure.” I had a great career at Dell Technologies and stayed busy, so I didn’t think much more about it.

Then one day she came to me with detailed specifications for two large engraving machines. She said, “Here’s what I’ve found. These are the two I like. Which one do you think is better?” I chose the larger model, and a few weeks later we were the proud owners of an AP Lazer 2816 CO₂ engraving machine.

With my background in electrical and mechanical systems, I dove straight into learning everything it could do. My first project was to recreate the Christmas ornaments she loved. They turned out beautifully. Since it was close to the holidays, we hand‑delivered more than 50 ornaments to friends and family.

As I continued experimenting and making custom pieces for friends, word spread quickly. The phone started ringing. One project led to another, and before long, what began as a simple curiosity became a growing business.

Today, I’m a member of the Liberty Hill Achievers BNI Network and actively involved in the community. ATX Laser Designs has grown far beyond those first ornaments, and in just a few months, I’ll be bringing on my first employee. What started as a question — “How was this made?” — has become a craft, a business, and a new chapter I never expected but now can’t imagine living without.

We all face challenges, but looking back would you describe it as a relatively smooth road?

Like most small business owners, my journey hasn’t been without challenges. When we first brought the AP Lazer home, I quickly realized that owning a machine and mastering it were two very different things. Even with my electrical and mechanical background, there was a steep learning curve. Every material behaves differently, every project requires precision, and every mistake teaches you something new — sometimes the hard way.

Another challenge was simply time. I was still working full‑time at Dell, learning the laser in the evenings, and taking on small projects whenever I could. Balancing all of that while trying to build something meaningful wasn’t easy, but it pushed me to become more disciplined and intentional with my time.

As the business grew, I faced the challenge of shifting from “doing everything myself” to building something sustainable. That meant developing processes, learning the business side of things, and preparing to bring on my first employee — a big milestone, but also a big responsibility.

And like many local businesses, getting my name out there took patience. Word of mouth is powerful, but it takes time to build. Joining the Liberty Hill Achievers BNI Network helped tremendously, but I had to learn how to talk about what I do, how to present my work, and how to build relationships in a way that felt authentic.

Every challenge has shaped the business into what it is today. They’ve pushed me to grow, to adapt, and to take pride not just in the finished products, but in the process of building something from the ground up.

Thanks – so what else should our readers know about ATX Laser Designs?

I’m not the kind of laser engraver who focuses on one product or churns out the same item over and over. You won’t find me making a line of cups with funny sayings or mass‑produced graphics. That’s just not who I am or why I started this business.

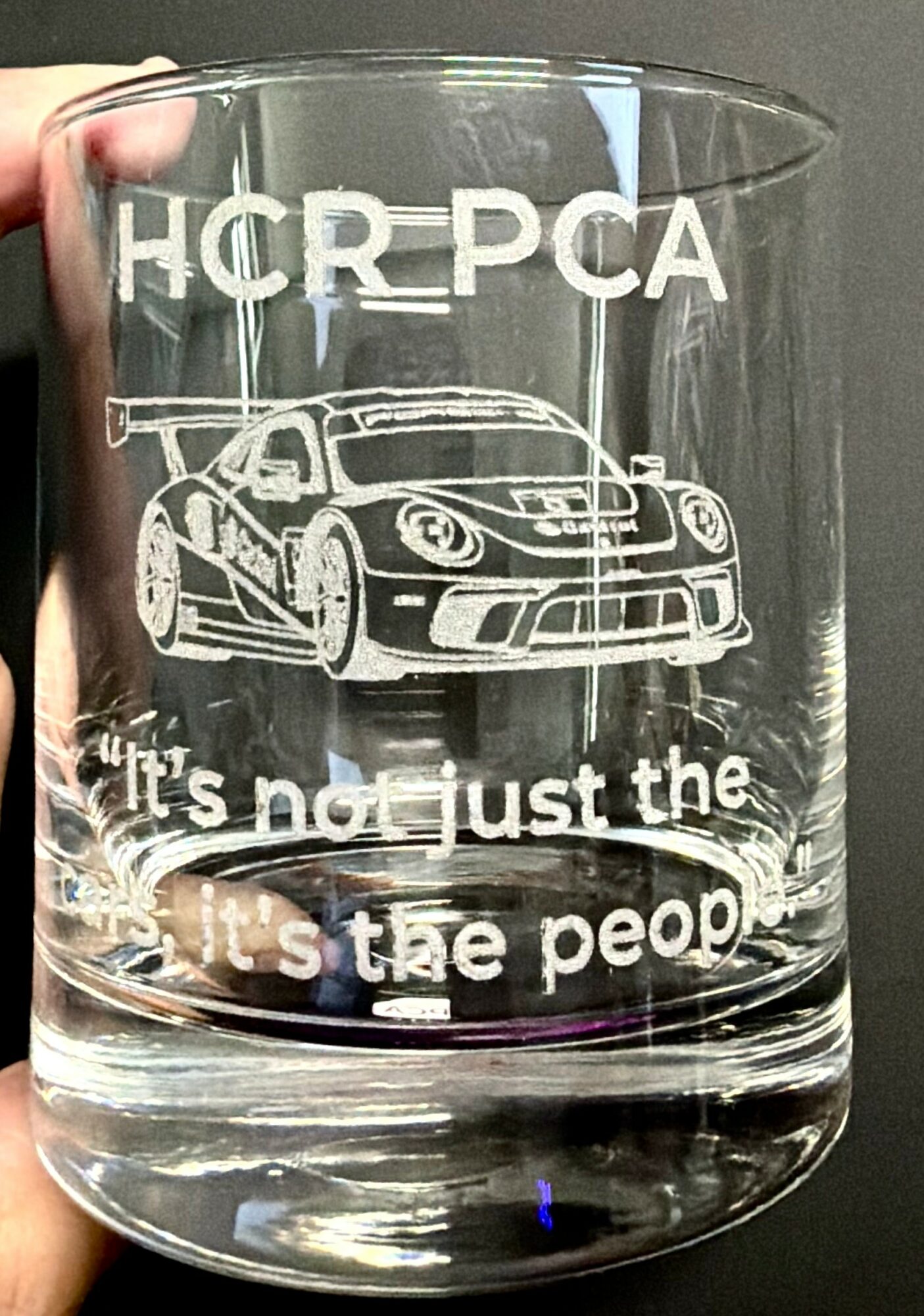

I’m a custom engraver at heart. I love taking a customer’s idea — sometimes fully formed, sometimes just a spark — and turning it into something meaningful and treasured. Every project is different, and that’s what keeps me inspired.

Not all items are straightforward to engrave. In fact, many of the pieces people bring me aren’t naturally suited to lay flat on a laser bed at all. That’s where my background in electrical and mechanical systems becomes a real advantage. I take pride in being able to engrave on items that most shops would turn away.

Sometimes that means designing and building a custom fixture to hold an object securely — like twisted liquor bottles, irregular keepsakes, or uniquely shaped heirlooms. I enjoy the challenge. It’s problem‑solving, craftsmanship, and creativity all working together.

For me, it’s never about mass production. It’s about honoring the story behind each piece and creating something that truly matters to the person receiving it.

Do you have any advice for those just starting out?

When I first purchased my AP Lazer machine, one of the best pieces of advice I received was to attend their annual Lazer‑Con conference. At the time, I didn’t fully understand how valuable that suggestion was, but it ended up becoming a turning point in my journey.

Lazer‑Con isn’t just a training event — it’s where engravers from all over the country come together to share knowledge, troubleshoot challenges, and learn from one another’s successes and mistakes. The information you gain there is something you simply can’t get from manuals or online videos. It’s real‑world experience, shared openly by people who have been in the trenches.

Over the years, I’ve built friendships with engravers across the United States. We talk regularly, share what we’ve learned, and help each other avoid pitfalls. Sometimes a five‑minute conversation with someone who has “been there” can save hours of trial and error.

Networking has become one of the most important parts of my business. It’s helped me grow faster, solve problems more efficiently, and stay inspired. Being part of a community of engravers who genuinely want to see each other succeed has been invaluable — and it’s something I’m grateful for every day.

Contact Info:

- Website: https://atxlaserdesigns.com